操作范围:初涂固化炉、精涂固化炉、废气焚烧炉。

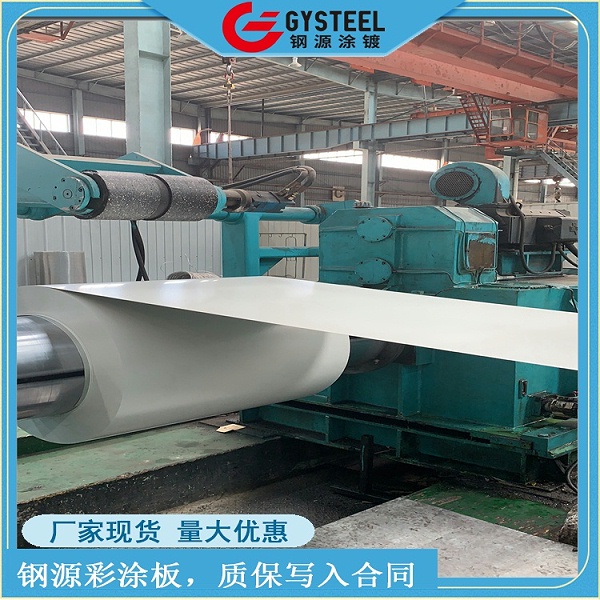

彩钢板生产线工艺描述:钢带从辊涂机出来,彩钢板生产线经过一段流平区即进入固化炉,钢带湿涂层在热风炉的脱水烘干后形成一定厚度的干膜。

焚烧炉:生产过程中,随时检查焚烧情况,即通过炉温和炉压来判断焚烧效果,并利用烟囱前的阀门来调节。另要通过废气输送风管闸板的开合控制好固化炉与焚烧炉之间压力平衡点。

Scope of operation: primary coating curing furnace, fine coating curing furnace, waste gas incinerator.

Process Description: the steel strip comes out of the roller coating machine and enters the curing furnace after passing through a section of leveling area. The wet coating of the steel strip forms a certain thickness of dry film after dehydration

and drying in the hot blast furnace.

Site management standard: before shift: remove the floating dirt in the curing furnace, start the circulating fan and exhaust fan for air cleaning, clean the combustible gas concentration alarm device, and approve the set value of the lower

limit of explosion concentration. Confirm that the system interlock of combustible gas concentration alarm and curing furnace heating device is effective, and raise the temperature in sections according to the heating curve of primary and fine coating

curing process. Wash the incinerator and raise the temperature to the set value. After shift: after the heater stops working, the circulating fan and exhaust fan still work for a period of time to cool the furnace and remove the waste gas in the furnace

and clean the surrounding area.

Production process:

Curing furnace: the temperature control curve in the furnace is directly related to the process conditions such as steel strip thickness, coating type, coating thickness and unit speed. Although the preset value can be made according to experience,

the accurate value should be corrected according to the dry film performance test. Therefore, in the production process, the coating should be cured regularly and cooled to room temperature, and then the on-line MEK and pencil hardness test should

be conducted, Adjust furnace temperature curve at any time.

Incinerator: during the production process, check the burning situation at any time, that is, judge the burning effect by furnace temperature and pressure, and use the valve in front of the chimney to adjust. In addition, the pressure balance

point between the curing furnace and the incinerator should be well controlled through the opening and closing of the air pipe ram for waste gas transmission.