彩钢板活动房的四大优点以及保养

天物彩板专注彩板行业16年——天津彩涂卷有什么品牌_安装彩钢板活动房_天物彩板请拨打网站上方电话咨询

在我们的生活中,彩钢板的应用还比较广泛,涉及到很多领域。由于其便利性和价格能够满足大家的需求,其市场正在逐步扩大,特别是在彩钢板活动房市场,得到了很多消费者的认可。让我们来看看这些优点以及应该如何维护。

一。彩钢板活动室具有重量轻、强度高、保温隔热、美观耐用等优点,是集建筑与装饰于一体的高层建筑。彩钢板活动房施工简单,广泛应用于大跨度厂房、仓库、办公楼、冷库、商店、临时用房等场所。从彩钢板的特性出发,分析了彩钢板活动房屋的一些特性。接下来,让我们了解彩钢板的特点以及彩钢板移动车间的特点和性能。

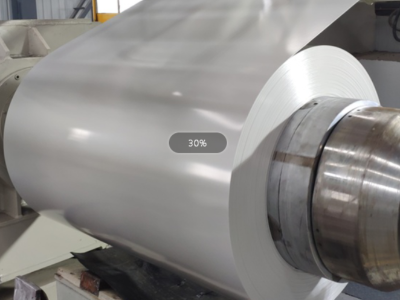

2。彩钢板涂料是由冷轧钢板和镀锌钢板经表面化学处理、辊涂、复合有机薄膜,然后烘烤固化而成的产品。有人称此产品为“预卷彩钢板”和“塑料彩钢板”。彩钢板产品是生产厂家在连续生产线上生产的,所以又称彩钢板卷。

三。彩钢板不仅具有机械强度高、易成型的钢材性能,而且具有良好的装饰性和耐腐蚀性。

四。彩钢夹芯重量小于14kg,可充分减轻结构荷载,降低活动房屋的结构成本。彩钢瓦具有许多优良的特性和性能,具体如下。

1) 易于安装

彩钢板活动房具有重量轻、拼接安装、易切割等特点,安装方便,大大节省了施工时间,提高了效率。

2) 耐久性

3) 经特殊涂层处理的彩钢板使用寿命约15年,每10年喷涂一次防腐层,活动屋面板使用寿命可达到35年以上。

4) 美观

彩钢压型钢板有几十种颜色,可以满足任何风格的移动建筑的需要,满足不同的需要。

5) 保温

彩钢复合板常用的保温材料有岩棉、聚氨酯等,导热系数低。活动室具有良好的保温隔热效果。高强度彩钢板采用高强度钢板为基材,加上先进的设计和辊弯成形。因此,彩钢活动房具有良好的结构特点。

彩钢活动房的维护

1、 定期防锈防腐:

采用金属涂层防护方法,对构件表面进行涂层和塑料保护,使其接触周围的腐蚀介质,达到防锈、防腐的目的。然后定期检查钢结构的保护层是否完好,并及时进行保护。

彩钢板活动室

2、 定期变形检查及防护:

通过对本工程梁、桁架的外观检查,发现桁架下弦挠度过大,桁架平面变形,屋面局部不平,内吊顶及油漆开裂等,可认为梁、桁架有异常变形,并进行数据测量和修复。

3、 其他疾病的观察和保护:

检查螺栓、焊缝、铆钉等连接处有无裂纹、松动、损伤,整个结构变形是否异常或超出正常变形范围。为了保证安全,应该及时修理

In our life, the application of color steel plate is still relatively extensive, and it involves many fields. Because its convenience and price can meet everyone's demand, its market is gradually expanding, especially in the color steel plate activity

room market, which has been recognized by many consumers. Let's take a look at the advantages and should How to maintain.

1. The color steel plate activity room has the advantages of light weight, high strength, heat preservation and insulation, beautiful and durable, and it is a high-level building integrating building and decoration. The construction of color steel plate

movable house is simple, and it is widely used in large-span workshop, warehouse, office building, cold storage, shop, temporary house and other places. Some characteristic properties of color steel plate mobile house are also taken from the characteristics

of color steel plate. Next, let's understand the characteristics of color steel plate and the characteristics and performance of color steel plate movable workshop.

2. The color steel plate coating is a product made of cold-rolled steel plate and

galvanized steel plate, after surface chemical treatment, roller coating, composite organic film, and then baking and curing. Some people call this product "pre roll color coated steel plate" and "plastic color steel plate". Color steel plate products

are produced by manufacturers in continuous production line, so it is also called color coated steel plate roll.

3. Color steel plate not only has the properties of high mechanical strength and easy forming of steel materials, but also has the good

decorative and corrosion resistance of coating materials.

4. The weight of color steel sandwich panel is less than 14 kg, which can fully reduce the load of the structure and reduce the structural cost of the mobile house. Color steel tile has many

excellent characteristics and properties, as follows.

1) Easy to install

The color steel plate movable room has the characteristics of light weight, splicing installation and free cutting, so the movable room is convenient to install, greatly

saving construction time and improving efficiency.

2) durability

3) The service life of color steel plate treated by special coating is about 15 years, and the service life of movable house plate can reach more than 35 years by spraying anticorrosive

coating every ten years.

4) beautiful

Profiled color steel plate has dozens of colors, which can meet the needs of any style of mobile buildings and meet different needs.

5) Thermal insulation

The common thermal insulation materials

of color steel composite board are rock wool, polyurethane, etc., with low thermal conductivity. The activity room has good heat preservation and insulation effect. High strength color steel plate adopts high strength steel plate as base material, plus

advanced design and roll forming. Therefore, the color steel movable house has good structural characteristics.

Maintenance of color steel movable room

1、 Regular anti rust and anti-corrosion protection:

The metal coating protection

method is adopted, and the component surface is protected by coating and plastic to touch the surrounding corrosive medium, so as to achieve the purpose of anti rust and anti-corrosion. After that, check whether the protective coating of steel structure

is intact regularly and protect it in time.

Color steel plate activity room

2、 Regular deformation inspection and protection:

Through the appearance inspection of beams and trusses in the project, it is found that the deflection of the

lower chord of trusses is too large, the plane of trusses is distorted, the roof is partially uneven, the inner ceiling and painting are cracked, etc. It can be considered that the beam and truss have abnormal deformation, and data measurement and repair

should be carried out.

3、 Viewing and protection of other diseases:

Check whether there are cracks, looseness and damage at the joints of bolts, welds, rivets, etc. Whether the deformation of the whole structure is abnormal or beyond the normal

deformation scale. In order to ensure safety, it should be repaired in time