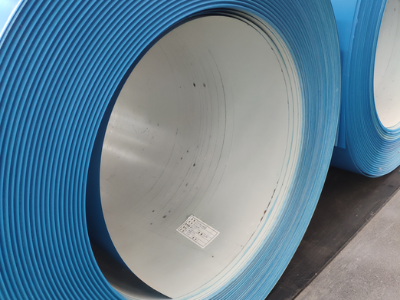

天物彩板专注彩板16年——本文章仅介绍彩钢板涂料品种,如咨询河北彩钢瓦多少钱一平方请拨打网站上方电话免费咨询

彩钢板涂料(涂料)品种(实际使用寿命远比美观寿命长)1:PE(一般聚酯),美观寿命7-10年,盐雾试验周期480h,使用量大,耐久性一般,主要用于一般工业厂房、仓储物流。仓库,机械加工厂;2:SMP(硅改性聚酯),漂白。光亮寿命8-12年,盐雾试验周期600小时,是普通聚酯PE的1.25倍。

彩涂铝卷报价涂料从失光到变色的时间(不同的环境和职业对美观寿命也有一定的影响),实际使用寿命比美观寿命长得多。使用寿命包括:涂层的光泽损失<涂层变色<涂层粉末化<涂层开裂<涂层起泡<白锈(涂层腐蚀)<红锈(钢板)。腐蚀)<钢板穿孔<钢板损耗效应。

Color steel plate coating (coating) variety (actual service life is far longer than beautiful life) 1: PE (general polyester), beautiful life 7-10 years, salt spray test cycle 480h, large use, general durability, mainly used in general industrial plants,

warehousing logistics. Warehouse, machining plant; 2: SMP (silicon modified polyester), bleaching. Bright life 8-12 years, salt spray test cycle 600 hours, is 1.25 times of ordinary polyester PE.

The coating is hard, wear-resistant and hard

to crush. It is suitable for windblown sand, iron ore, coal mine and other bad areas. The coating cost is 350 yuan / T 3: HDP: high durability polyester, 15 years quality assurance, 720 hours salt spray test cycle, 1.5 times of polyester, with good

durability and high cost performance. The cost of coating is only higher than that of polyester. Ester: 700 yuan / ton.

PVDF fluorocarbon polyvinylidene fluoride 20 years quality assurance, salt spray test cycle 720 hours, is twice that of ordinary

polyester, color plate king, UV resistance, acid-base resistance is very strong, the national key projects (high-speed railway station, gymnasium, etc.) generally use coating cost is only higher than ordinary polyester 2340 yuan / ton high durability

polyester color steel plate and fluorocarbon color steel plate. Non ferrous metal movement, steel works, power plants, chemical plants and other high pollution industries and regions), coastal areas with high salt fog and high UV light have a better

life.

The time from loss of light to discoloration (different environments and occupations also have a certain impact on the aesthetic life), the actual service life is much longer than the aesthetic life. Service life includes: gloss loss of

coating < discoloration of coating < powder coating < cracking of coating < blistering of coating < white rust (coating corrosion) < red rust (steel plate). Corrosion) < steel plate perforation < steel plate loss effect.