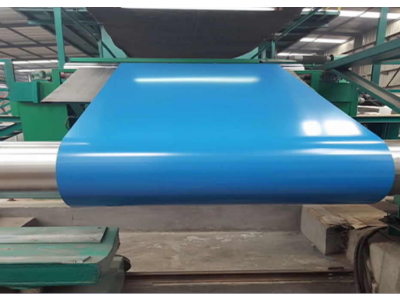

彩钢卷会成为主流工艺吗

天物彩板专注彩板行业16年——900轻钢彩板规格_彩钢卷参数颜色请拨打网站上方电话咨询

生产工艺包括钢带预处理工艺、底漆涂装工艺、底漆烘烤工艺、面漆涂装工艺、面漆烘烤工艺和牵引卷绕工艺。采用高质量的基板,对基板的表面、形状和尺寸精度的要求越来越高。室外使用,如小锌花板热镀锌钢卷、非锌花板热镀锌钢卷、锌合金热镀锌钢卷及时升起;室内使用,如电镀锌钢卷、覆膜冷轧板和铝卷。

主要技术是改进预处理工艺和预处理液,设备少,成本低。预处理液的稳定性、耐腐蚀性和环保性能不断提高。注意再涂技术的发展,提高普通聚酯、聚偏氟乙烯(PVDF)和塑性溶胶的性能,获得超显色性、抗紫外线、抗二氧化硫、耐腐蚀性;开发耐污染、吸热等功能涂料

单位设备更加完善。如新的焊接机、新的辊涂机、完善的固化炉、先进的自动化仪表等,由于冷压的成本低于热压,具有美观、立体感强等特点,冷压花生产技术已成为发展趋势。基色钢板的上表面必须进行电抛光,不得有灰尘、油脂、污染和生锈;涂漆前必须用干布将上面的灰尘擦干净

油漆分为底漆和面漆,即防腐底漆和表面面漆。防腐底漆一般不少于两层。涂装过程中应避免雨天和大风天气。夏季涂装温度应高于5℃,不高于35℃。油漆应连续,以避免底部暴露。

主要施工法4.1施工环境a.施工环境温度-1530℃,相对湿度不大于80%。当施工环境温度低于10℃时,应采取加热、加温措施。b、 防腐施工前,根据施工环境温度、湿度、原材料及工作特点,通过大面积施工前的试验,选择合适的施工配合比和施工操作方法。

The production process includes steel strip pretreatment process, primer coating process, primer baking process, finish coating process, finish baking process and traction winding process. Using high-quality substrate, the requirements for the surface,

shape and dimensional accuracy of the substrate are getting higher and higher. For outdoor use, such as small zinc flower flat hot-dip galvanized steel coil, non zinc flower flat hot-dip galvanized steel coil, the zinc alloy hot-dip galvanized steel

coil rising in time; for indoor use, such as electric galvanized steel coil, film coated cold-rolled plate and aluminum coil.

The main technology is to improve the pretreatment process and the pretreatment fluid, with less equipment and low cost. The stability, corrosion resistance and environmental protection performance of the pretreatment fluid are constantly improved. Note

the development of re coating, improve the general polyester, polyvinylidene fluoride (PVDF) and plastisol, obtain super color reproducibility, UV resistance, sulfur dioxide resistance, and improve corrosion resistance; develop functional coatings such

as pollution resistance and heat absorption

The unit equipment is more perfect. For example, new welding machine, new roller coating machine, perfect curing furnace, advanced automatic instrument, etc. As the cost of cold embossing is lower than

that of hot embossing, which has the characteristics of beauty, three-dimensional sense and high strength, the production technology of cold embossing has become the development trend. The upper surface of the base color steel plate must be electrically

polished to be free of dust, grease, pollution and rust; the dust on it must be cleaned with a dry cloth before painting

The paint shall be divided into primer and finish coat, i.e. anticorrosive primer and surface finish coat. Generally, the anticorrosive

primer shall not be less than two coats. Rainy and windy weather shall be avoided during the painting process. In summer, the painting temperature shall be higher than 5 ℃ and not higher than 35 ℃. The painting shall be continuous to avoid bottom exposure.

Main construction method 4.1 construction environment a. the construction environment temperature should be - 1530 ℃, and the relative humidity should not be greater than 80%. When the construction environment temperature is lower than 10 ℃, heating

and warming measures shall be taken. b. Before anti-corrosion construction, according to the construction environment temperature, humidity, raw materials and working characteristics, the appropriate construction mix proportion and construction operation

method shall be selected through the test before large-area construction.