彩涂板与喷涂板的生产线有何区别

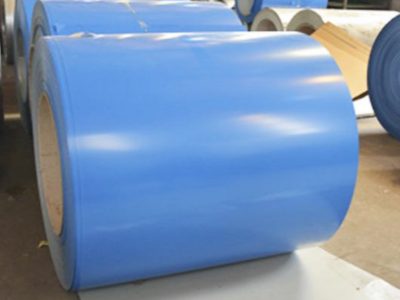

天物新产品,粉末喷涂彩板——高膜厚喷涂工艺,板面更饱满、更细腻 更多信息请拨打网站上方电话咨询了解

喷涂彩板的生产工艺最初是由金属成形后的粉末喷涂工艺发展而来的。这项技术已经领先于成形喷涂(又称粉末喷涂生产线)一大步。虽然粉末喷涂生产线也采用连续生产方式,但由于喷涂工艺仍采用喷枪布置形式,仍存在效率低、劳动强度高、涂层浪费大、涂层厚度不均匀等问题,与成形喷涂工艺相比,没有质的变化。因此,喷涂生产线已基本被彩涂板生产线所取代。

彩涂钢板是一种复合材料,它是通过对钢板表面进行脱脂和化学处理,在钢板表面滚涂特种涂料或涂膜后干燥固化而成。它将传统的喷涂改为钢板的连续喷涂,便于表面处理和涂层质量控制,且涂层中不存在边角和死角等易产生的缺陷。

与传统的粉末喷涂生产相比,彩钢板具有高效、节能、环保的优点。同时,它的综合成本也比喷板便宜。采用彩涂钢板工艺,可使薄板涂装产品成本降低5%~10%,节能1/6~1/5。但该喷涂工艺具有效率低、劳动强度高、油漆浪费大、漆膜厚度不均匀等优点。因此,喷涂生产线基本上被彩涂板生产线所取代。

The production process of spray plate originally evolved from the process of spraying powder after metal forming. This technology has been a big step ahead of forming spray, also known as powder spray production line. Although the powder spraying production

line also adopts continuous production mode, there are still problems such as low efficiency, high labor intensity, large waste of coating, uneven thickness of coating film and so on, because the coating process is still in the form of spray gun arrangement,

and there is no qualitative change compared with the forming spraying process. Therefore, the spraying production line has been basically replaced by the color coated plate production line.

The color coated steel plate is a kind of composite material,

which is made by degreasing and chemical treatment on the surface of steel plate and drying and curing after roller coating special coating or film on the surface of steel plate. It turns the traditional spray coating into the continuous coating of steel

plate, which is convenient for surface treatment and coating quality control, and there is no edge and dead angle and other defects that are easy to occur in coating.

Compared with the traditional powder spraying production, the color steel plate

has the advantages of high efficiency, energy saving and environmental protection. At the same time, its comprehensive cost is also cheaper than that of the spraying plate. Adopting the color coated steel plate process can reduce the cost of the thin

plate coating products by 5% ~ 10%, and save energy by 1 / 6 ~ 1 / 5. However, the spraying process has the advantages of low efficiency, high labor intensity, large paint waste and uneven film thickness. Therefore, the spraying production line is basically

replaced by the color coated plate production line.