印花板的特点

唐山天物彩板专注彩板16年——孝感印花板厂家直销_孝感印花板规格齐全 更多信息请拨打网站上方电话咨询了解

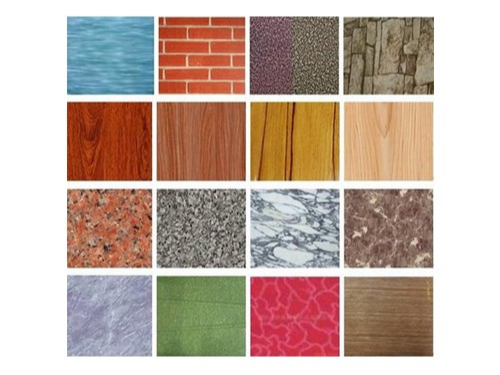

印花板是印有花纹或图案的彩涂板,是国外近几年才发展起来的一种新型家电板和建材装饰板。印花彩涂板是将

镀锌基板在涂层工序后经过表面印刷处理,获得各种不同图案的花纹这样一种产品,其外观比层板更美观、更课亮,刚性更高、性能更优越。随着人民生活水平的不断提高,这种产品必将越来越受到市场的青睐。在实际生产中,许多涂层产品的印花都是在单独的机组上进行的。这样的机组比较简单,只有一个开卷机、一台印花机座加热炉和一台卷取机组成。为了将花纹印到涂层板的涂膜上,首先要将花纹刻蚀到紫铜辊上,然后对铜辊镀铬,作为涂层印花用的印辊,其表面上的图案花纹是凹陷的,印辊从有色浆的料盘中沾取色浆,然后由刮刀将凹陷之外的色浆全部刮掉。当印辊与转印胶辊接触时,花纹内的色浆转移到转印胶辊上,最后印到钢板表面。再经过适当温度的加热烘干,花纹便很华固地附在钢板的涂膜上。

Printed board is a kind of color coated board with pattern or pattern. It is a new type of decorative board for household appliances and building materials developed in foreign countries in recent years. Printing color coating board will be

After the coating process, galvanized substrates are printed on the surface to obtain patterns of different patterns. The appearance of galvanized substrates is more beautiful, brighter, more rigid and better performance than laminates. With

the continuous improvement of people's living standards, this product will be more and more popular in the market.

In recent years, developed countries such as Japan and South Korea have intensified their efforts in these areas and are in the forefront of technology. Although great progress has been made in the development of high-grade printing technology

and equipment for color coated sheets in China, there is no such equipment in other production lines except on the No. 2 color coated sheet line imported by Baosteel, which is still a blank in this field.

Printed boards are usually finished by the production process of color coating line. At present, the widely used color painting production line is a two-coat and two-bake process, and its finishing machine is always equipped with two coat heads

for rapid color change of topcoat. In this production line, printing can be realized, that is, the back pattern is engraved on the glue roll of No. 1 finishing machine, the glue roll transfers the pattern to the coating roll, and the coating roll

transfers the pattern to the steel strip for printing. After drying, the No. 2 finishing machine coats varnish or transparent protective film on the surface.

In actual production, many coated products are printed on a separate unit. Such a unit is relatively simple, consisting of only one uncoiler, a printing stand heating furnace and a coiler. In order to print the pattern on the coating film of

the coating plate, first etch the pattern on the copper roller, then chromium plating on the copper roller, which is used as the printing roller for coating printing. The pattern on the surface of the roller is concave. The printing roller is stained

with the paste from the disc of the paste, and then the paste outside the depression is scraped off by the scraper. When the printing roll contacts with the transfer roll, the paste in the pattern is transferred to the transfer roll and finally printed

on the surface of the steel plate. After heating and drying at appropriate temperature, the pattern is firmly attached to the coating of the steel plate.