影响铝板质量的因素有哪些

天物彩板最新产品粉末喷涂彩板——粉末喷涂技术质保15年不褪色,详细请拨打网站上方电话咨询

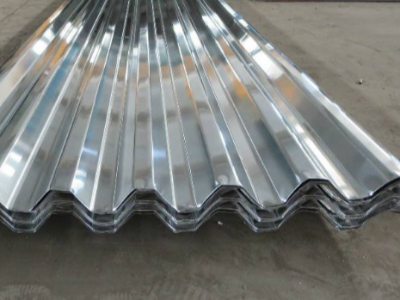

作为一种幕墙材料,如果没有配套的质量,对用户来说是非常危险的,建筑工程的安全和质量也无法保证。这对整个铝单板行业是非常不利的。低价销售的劣质铝单板会让用户对铝单板产品失去信心。因此,我们必须坚决抵制劣质铝板产品。

在铝单板工业中,质量不仅影响装饰效果,而且影响使用性能。那么,影响铝单板质量的因素有哪些?这里有一个简短的介绍。

一。

偷工减料

随着国家质量监控体系的不断完善,偷工减料现象并不像以前那样猖獗,但仍有一些企业为了降低生产成本,铤而走险,在生产铝单板产品的过程中,偷工减料,使用不合格的模具,导致铝型材壁厚不合格。

2。混合原料

由于铝单板行业缺乏相对完善和成熟的行业标准,原材料质量参差不齐。一些企业为了在激烈的市场竞争中低价取胜,在原材料中采用不同成分的杂铝或混合再生铝,以降低生产成本。

三。监管不严

一些企业监管制度不健全,原料监管存在漏洞,致使部分化学元素不合格的原料混入其中,造成铝单板产品中化学元素严重超标的现象。

四。不合时宜的测量

在铝单板的涂装过程中,需要溶液病毒。在配置过程中,如果不按照相关规定进行配置,不及时测量溶液浓度,氧化膜就会变薄,达不到标准厚度。

5个。欺诈

铝单板产品的结算依据是经销商与客户之间的结算依据是面积,经销商与制造商之间的结算依据是重量。不同的结算基础也使得一些厂家投机取巧,在壁厚问题上下了很大功夫。

As a curtain wall material, if there is no matching quality, it is very dangerous for users, and the safety and quality of construction engineering can not be guaranteed. It is very unfavorable for the whole aluminum veneer industry. Low quality aluminum

veneers sold at low prices will make users lose confidence in aluminum veneer products. Therefore, we must firmly resist low-quality aluminum sheet products.

In the aluminum veneer industry, the quality will not only affect the decoration effect, but also affect the usability. So, what are the factors that affect the quality of aluminum veneer? Here is a brief introduction.

1. Jerry building

With

the continuous improvement of the national quality monitoring system, the phenomenon of Jerry building is not as rampant as before, but there are still some enterprises in order to reduce production costs, desperate, in the process of production of aluminum

veneer products, Jerry building, using substandard molds, resulting in unqualified wall thickness of aluminum stress bar.

2. Mixed raw materials

Due to the lack of a relatively perfect and mature industry standard in the aluminum veneer industry,

the raw material quality is uneven. Some enterprises want to win in the fierce market competition at a low price, so they use miscellaneous aluminum with different components or mix recycled aluminum in the raw materials to reduce the production cost.

3. Lax supervision

Some enterprises have not established a perfect supervision system, and there are loopholes in the supervision of raw materials, so that some raw materials with substandard chemical elements are mixed into them, resulting in

the phenomenon that the chemical elements contained in the aluminum veneer products exceed the standard seriously.

4. Untimely measurement

In the coating process of aluminum veneer, solution virus is needed. In the process of configuration,

if the configuration is not carried out according to the relevant regulations and the concentration of the solution is not measured in time, the oxide film will be thinner and can not reach the standard thickness.

5. Fraud

The settlement basis

of aluminum veneer products is that the settlement basis between dealers and customers is area, and the settlement basis between dealers and manufacturers is weight. Different settlement basis also makes some manufacturers opportunistic and make great

efforts on the issue of wall thickness.