天物彩板专注彩板定制16年——更多北京净化彩钢板_净化彩钢板施工条件请拨打网站上方电话咨询

净化彩钢板不使用木质材料和其他不符合洁净标准要求的材料。

1.2.4净化彩钢板屋面超起缩缝施工方案彩钢板吊顶固定在起缩缝顶部的T型铝上,另一侧固定在T型铝上。

Construction Conditions of Clean Engineering

1.1.1. Wood materials and other materials that do not meet the requirements of clean standards are not used in clean rooms of clean engineering.

1.1.2. Clean engineering materials are stored

in a clean and dry environment with enclosure facilities.

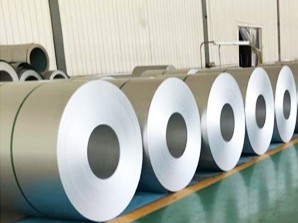

1.1.3. The thickness, specifications, dimensions and quality of the color steel plate for clean engineering must meet the design requirements or contract requirements, and the factory

inspection report is provided. The production of the color steel plate must be carried out in accordance with the secondly designed jigsaw and the list of sizes and quantities. In the production process, according to the drawing number, the length

of the ceiling plate should not exceed 5000 feet.

1.1.4 Clean engineering auxiliary materials, such as hardware standard parts, must meet the design requirements or contract requirements and have factory certificates. 1.1.5. The material and

specification of the section steel for clean Engineering connection shall meet the design requirements, and low carbon steel shall be used with quality guarantee or inspection report.

1.1.6. The materials and specifications of aluminium alloy

profiles for clean engineering shall conform to the design requirements or contract requirements, and have a factory certificate of qualification.

1.1.7. There are sufficient temporary storage sites for materials and for processing and semi-finished

products of aluminium alloys in the clean engineering.

Construction Method of Clean Engineering

1.2.1. The dew-proof construction of glass windows. In the workshop, the room temperature is mostly about 22 degrees Celsius, while the corridor

is between 18 and 28 degrees Celsius, which results in temperature difference. According to the calculation of thermal resistance and heat transfer of glass, there will be frost phenomenon (outside the window of the room), and the experience is the

same, such as the browning of Zhuhai multi-storey. This phenomenon exists between the wire harvesting boards.

1.2.2. There are many wet processes in PCD process of waterproofing construction of partition wall in clean engineering, and the solution

used in the production process is corrosive, which corrodes the color steel plate wall and affects the life of partition wall. Therefore, it is suggested that a cement foundation or a 50_wide civil structure with 80-100_high under the color steel

plate partition wall should be designed for the partition wall in this workshop. It is specially made bricks, and then painted steel plate is made on them. If it is on the side of the purification workshop, Guangzhou Zijing specially designed and

used profiles (big arc) to meet the requirements of the clean room. It is not on the side of the clean workshop that terrazzo and acid-resistant tiles are pasted on the top to ensure beautiful appearance.

1.2.3. There are many wet and corrosive

PCD processes in the anti-corrosion construction of color steel plate wall of clean engineering. Corrosion of coloured steel sheets for partition walls in this kind of workshop often results in the replacement of coloured steel sheets after they are

used for a short time. Guangzhou Zijing has done similar projects in the past. For workshops with corrosive articles, the conventional anticorrosion treatment of color steel plate walls is as follows:

A. Antiseptic cement spraying for wall surface

of clean engineering;

B. Use acid and alkaline paint to brush the panel on the wall. (In this way, the life of the color steel plate can be prolonged by 5-6 years, and the normal use of stone markings is about 3 years, so replacement should

be considered.)

1.2.4. Construction scheme of over-lifting and shrinking joints of color steel plate roof for clean Engineering The color steel plate ceiling is fixed on T-shaped aluminium on the top of lifting and shrinking joints, and on the

other side is put on T-shaped aluminium.

Clean engineering construction scheme: