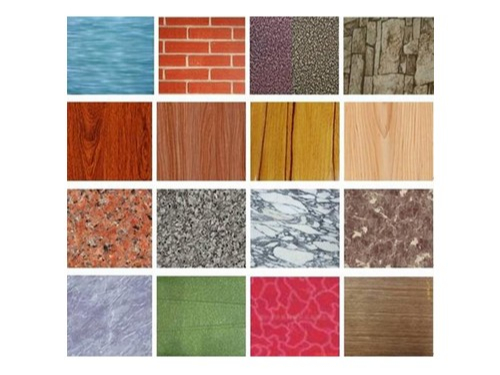

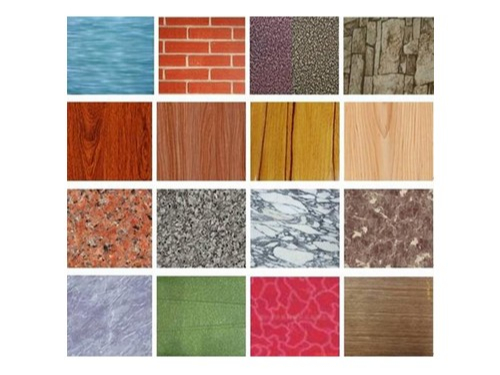

印花彩板的形成方法

印花彩色涂层板的锌层冷却后,其表面会形成一种晶粒形态,称为锌花。锌花的形成可分为多种途径。今天,我们主要带您了解以下几点:

喷水法:当镀锌板表面的纯锌溶液不凝固时,喷水(水与蒸汽、水与空气的混合物)形成晶核。未溶解的锌液从这一点向外扩散,形成锌花。

印花彩色涂层板表面吹塑法:当印刷彩色涂布板上的纯锌层即将凝固时,如果锌晶体能通过蒸汽流或二氧化硫流顺利生长,则可获得较大的图案。该方法还可以形成致密的氧化膜,提高镀锌层的耐蚀性。

印花彩色涂层板丝

网法:此方法仅适用于薄镀锌印刷层。采用磁力辊使钢丝网与锌层表面接触,达到此目的。当丝网接头的接触首先冷却时,产品的固体颗粒形成并变成核,而其他未溶解的锌液体开始结晶成核并向外膨胀形成锌火花。

印花彩色涂层板的生产关系到成品的质量。如果我们需要在印刷的彩涂板上制作大型锌邮票,我们需要考虑综合因素。以上资料仅供参考。如果您对产品有更多的细节,请随时与我们联系。

After the zinc layer of the printed color coated sheet is cooled, a kind of grain morphology will be formed on its surface, which is called zinc flower. The formation of zinc flower can be divided into many ways. Today, we mainly take you to know the

following points:

Water spraying method: When the pure zinc solution on the surface of galvanized sheet does not solidify, the crystal nucleus is formed by spraying water mist (mixture of water and steam, water and air). The undissolved zinc liquid diffuses outward from

this point to form zinc flower.

Surface blowing method: When the pure zinc layer on the printed color coating board is about to solidify, if the zinc crystal can grow smoothly through steam flow or sulfur dioxide flow, larger patterns can be obtained.

The method can also form a dense oxide film and improve the corrosion resistance of galvanized layer.

Wire mesh method: This method is only applicable to thin galvanized printing layer. It uses magnetic roller to make the wire mesh contact with

the zinc layer surface to achieve this purpose. As the contact of the wire mesh joint is cooled first, the solid particles of the product form and become nuclei, while other undissolved zinc liquids begin to crystallize as nuclei and expand outward to

form zinc sparks.

The production of zinc flower is related to the quality of finished products. If we need to make large zinc stamps on the printed color coating board, we need to consider the comprehensive factors. The above information is for

reference only. If you have more details about the product, please feel free to contact us.